In our latest chapter of informative blog offerings from Polyglass, today we will focus on steep-slope underlayments, from the required basic Code underlayments to the superior leak barriers of self-adhesive underlayments. Polyglass as a leader in this product category, has engineered numerous Polystick self-adhesive membranes that can be the ideal membrane for any project size, style, type, and performance level, with a focus on in particular Polystick P.

There is no worse sinking feeling as a roofing contractor than the client who calls you with leakage entering their building due to problems with the roof you are working on or even completed. Though no product can overcome poor workmanship, some do have the unique forgiving characteristics to perform well even when not installed in an ideal manner. Self-adhered carrierless ice and water high-temp underlayment like Polystick P with quality design and fabrication can offer peace of mind and advantages not possible with traditional felts.

The Advantages of Self-Adhesive Underlayments for Roofing Contractors

Roofing contractors can face many challenges when it comes to ensuring the durability, efficiency, and quality of the roofing they install. A critical component with steep-roofing designs is the underlayment, which serves as the protective layer between the roof covering and the roof deck. While traditional code-compliant felts may be widely used and normal, the evolution to self-adhered roof underlayments has revolutionized the industry. These performance-driven materials offer significant advantages that benefit roofing contractors in various ways, from ease of installation to enhanced performance and long-term durability.

Simplified Installation Methods

A key benefit of self-adhered roof underlayments, like our Polystick P, is the streamlined installation process for roofing contractors. Traditional felts often require thousands of nails, staples, or additional adhesive flashings to secure them to the roof deck. This method can be time-consuming, labor-intensive, and susceptible to errors, especially when creating an ice-damming membrane or leak barrier with multiple layers of felt. In contrast, self-adhered underlayments feature a pre-applied adhesive layer, allowing contractors to simply remove a release film and bond the material directly to the roof deck.

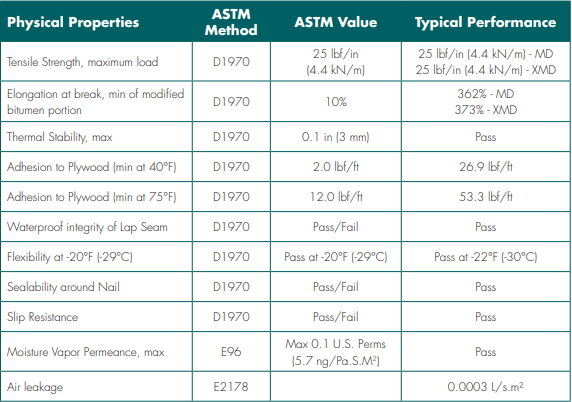

During installation, underlayments require fasteners to penetrate the material. Traditional felt typically needs fasteners throughout the roof field and at laps, with poor fastener sealing ability. Self-adhesive membranes like Polystick P only require blind backnailing at the laps. Complying with ASTM D 1970 for nail sealability ensures that fasteners will not allow water to penetrate, regardless of weather intensity.

This self-adhesive approach can reduce overall installation time, enabling contractors to complete projects faster and move on to the next job sooner. With ongoing worker shortages, the ease of installation allows less-skilled workers to manage the task efficiently, freeing up more experienced workers for other critical aspects of the roofing project. This streamlined process not only saves time but can also reduce labor costs, ultimately increasing the profitability of roofing jobs.

Moreover, the Polystick P carrierless membrane is highly flexible, making it ideal for flashing around roof penetrations, transitions, and other critical areas. While Polystick P is designed primarily for metal roofing, it is also versatile enough to be used beneath asphalt shingles, synthetic tiles, and other approved roofing materials.

Adhesion and Seam Integrity Improved

The adhesive backing of our Polystick P, like many of our other self-adhered roof underlayments, provides superior adhesion to the roof deck. This strong bond ensures that the underlayment stays in place even under challenging weather conditions, such as high winds or heavy rain. The adhesive layer also acts as a sealant, preventing water, air, and moisture from penetrating the roof deck.

This enhanced sealing capability is particularly beneficial in areas prone to extreme weather conditions. Roofing contractors can be confident that their installations will remain secure and watertight, reducing the likelihood of callbacks due to leaks or other issues. The result is not only satisfied customers but also a boost to the contractor’s reputation for quality workmanship. Even if damaged during or after installation, water cannot travel beneath the underlayment thanks to its continuous bond to the decking.

Longevity and Durability

Polystick P along with our entire Polystick product line of roofing underlayments are specifically designed with superior performance and durability in mind. They are factory-fabricated using high-quality raw materials such as modified bitumen/polymers and surface carriers for traction even when wet. Self-adhesive membranes offer superior durability as compared to traditional felts, which can quickly degrade when subject to rain and UV exposure, especially when exposed to temperature fluctuations, or physical damage during roof installation.

The durability of self-adhered underlayments translates to longer-lasting roofing systems. Contractors can assure their clients that the roofs they install will have an extended lifespan, which is a key selling point in today’s competitive market. Moreover, the reduced need for maintenance and repairs due to the robustness of these materials means fewer future headaches for contractors and homeowners alike.

Weather Protection and Fire Resistance

Weather resistance is a critical factor in the performance of any roofing system, and self-adhered underlayments like Polystick P excel in this area. These materials are designed to withstand a wide range of environmental conditions, including heavy rain, snow, ice, and extreme temperatures. Their ability to create a continuous, airtight barrier helps protect the roof deck from water infiltration, ice dams, and wind-driven rain.

For roofing contractors, this means fewer concerns about potential failures or damage caused by harsh weather. In regions where severe weather is common, using self-adhered high-temperature underlayments can be a significant selling point, as they provide an added layer of protection that traditional underlayments might not offer. This added security can lead to increased customer satisfaction and potentially higher referrals.

Enhanced Safety for Workers

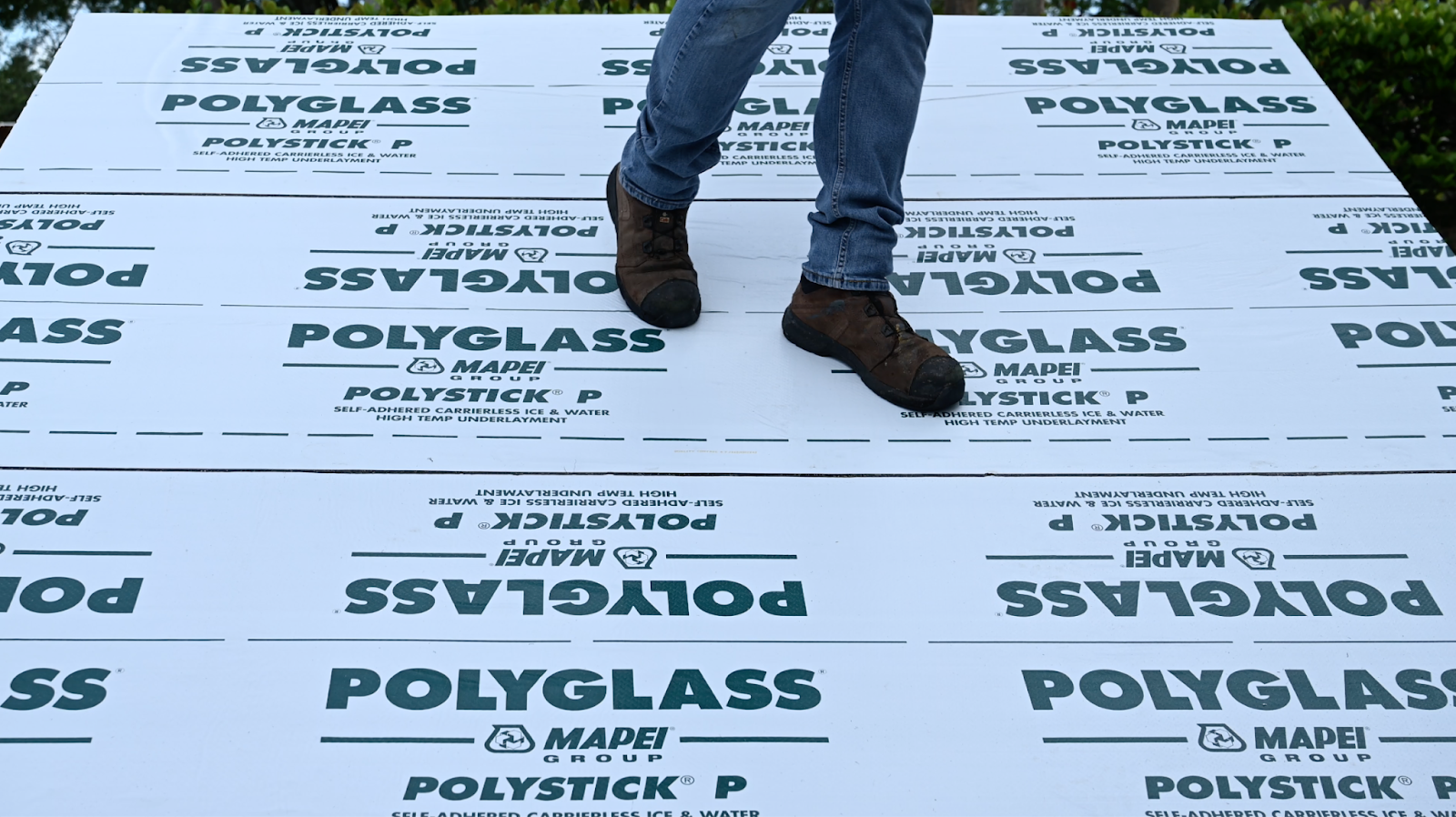

Safety is a significant concern for roofing contractors, with a higher rate of falls than most other construction trades offering workers a safer slip-resistant work surface is important. The advanced surface film of Polystick P with specialized surface treatments, offers foot traction far exceeding anything offered by traditional felts for workers as they navigate the roof during installation.

By minimizing the risks associated with roofing work, contractors can focus more on precision and quality rather than safety concerns. This not only enhances the overall efficiency of the project but also contributes to a safer workplace, which is a critical aspect of maintaining a professional and responsible business.

Options Equal Sustainability

Many roofing contractors are seeking more sustainable materials to offer their clients. Self-adhered roof underlayments are designed with eco-friendliness in mind. Their long-lasting performance reduces the need to remove and replace them, even when installing a new metal roof covering system. Additionally, many self-adhered underlayments can be used as a second layer over existing ones, saving labor and reducing landfill waste.

By using self-adhered underlayments, contractors can position themselves as environmentally conscious, appealing to clients who prioritize sustainability. This approach not only helps protect the structure but also differentiates contractors in a competitive market, potentially leading to increased business opportunities.

Upgrade Your Roofing Projects with Polyglass’ Self-Adhered Underlayments

Polystick P, along with our extensive line of Polystick self-adhered roof underlayments, offers numerous benefits to roofing contractors, making them an ideal choice for today’s roofing environment. From simplified installation and enhanced durability to improved weather resistance and safety, these advanced materials equip contractors with the tools needed to deliver high-quality, long-lasting roofing solutions. As the demand for efficient, reliable, and sustainable roofing systems continues to rise, contractors who adopt self-adhered underlayments will be well-positioned to meet client needs and excel in the competitive roofing industry. Choose Polyglass for a superior roofing experience that ensures both performance and sustainability.